TECHNOLOGIST

Management Software

Keeping track of a dozen employees and 13,000 acres of farmland is a huge challenge. Throw in all of the research plots and different experimental management strategies we are implementing during any given season and the challenge becomes even greater. This is why we make great use of Granular farm management software. It allows us to keep track of basic necessities like planting and harvesting schedules, nutrient applications, input costs, and inventory. It also allows tasks to be assigned and their progress tracked to help synchronize the efforts of all of our employees, keeping our operation running smoothly. Additionally, scouting notes and images are taken in each field and uploaded immediately to be reviewed by anyone on the farm so that we can easily use those observations to help guide management decisions both in the short term (nutrient and fungicide applications for example) and in the long term (adjusting future planting dates and cover crop mixes to optimize impact).

BEING PRECISE AND EFFECTIVE

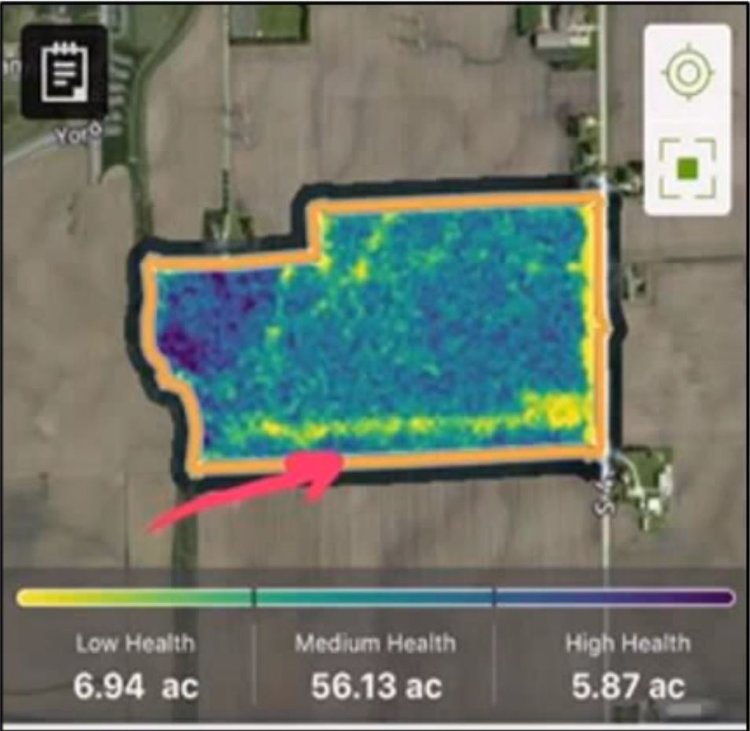

We are able to utilize GPS technology by connecting our seeders and fertilization equipment, including Martin dual fertilizer placement units for starter and y-drop nutrient applicators later on in the season. These pieces of equipment allow for very precise application of nitrogen when the plants need it most in amounts that the plants can use, limiting excess use and nutrient loss. During planting, differences in soil quality within each field are dealt with by products from Precision Planting like DeltaForce to control seed planting depth and e set drives that precisely measure out seed rates depending upon the soil type, temperature, and moisture. The combination improves planting accuracy, germination rates, and ultimately yield. Our GPS units are enhanced by the use of satellite imagery provided by Encirca to increase the effectiveness of our variable rate application and seeding equipment. We apply different amounts of pesticides, herbicides, and fertilizers to different parts of the field in order to match our application to the challenges faced by the different parts of each individual field. Encirca gives us daily images and reports of crop health for every 9 square meters, allowing us to manage our crops not even on an acre to acre level, but on a meter to meter level in the field. Encirca also helps us to focus scouting efforts, application rates, and helps us to determine the effectiveness of our management practices by showing changes in crop health over time.

Encirca lets us fully utilize variable rate planters and sprayers by taking into account historical yield data, soil test results, pest and weed pressures, and drainage characteristics of different locations within each field. We also have many other means of measuring field variability and conditions such as Trimble's GreenSeeker crop sensing system, which uses infrared light to measure and quantify variability in real time, similar to how our satellites determine crop health. After the measurement, a prescription plan is created to treat the variability of the crop. Our systems also record accurate field maps and yield maps in order to help us make future farm management decisions. Using Case-IH's AFS (Advanced Farming Systems) Connect, our meters automatically synchronize by accessing one data storage point in the cloud, giving us instant access to everything from yield data maps to engine diagnostics. This gives us instant access to powerful information from anywhere on the farm, helping us to be more adaptable to changing conditions and unforeseen challenges.

PRECISION Equipment

Case IH agricultural equipment helps facilitate much of our work in the field. Our equipment allows us to efficiently perform all our necessary tasks from cover crop termination to planting, fertilizing, and harvest. Each piece of equipment we use is fitted with a Selective Catalytic Reduction (SCR) system to meet Tier 4B emissions standards while maintaining peak engine power and increasing fuel economy. These standards started in 1996, when the U.S. Environmental Protection Agency (EPA) established the first off-highway diesel emissions standards with the implementation of Tier 1 regulations to limit nitrous oxides and particulate matter pollution from off-highway equipment. Limiting our nitrogen oxides and particulate matter emissions is important to limit smog, acid rain, maintain the nutrient balance in large bodies of water like the Chesapeake, and control tropospheric ozone levels. Current Tier 4B regulations (2014) require a 90% reduction in nitrogen oxide and particulate matter emissions from the equivalent Tier 3 vehicle.

INTEGRATIon of GLOBAL POSITIONING SYSTEMS

Our vehicles alone cannot make our production system efficient. We work to improve the efficiency of our systems from all angles, leading to our appreciation and use of precision agricultural practices. Precision agriculture is primarily concerned with managing crops no longer field by field, but meter by meter. This intra-field management has been made possible by integrating Global Positioning Systems (GPS) and our vehicles. These systems allow our equipment to drive themselves across the field within 1 inch of their intended path. Other equipment abilities like automatic sprayer shut offs and varied turning application rates eliminate overlapping and promote even coverage when desired.This incredible precision reduces skipped and overlapped areas, saving time, product, and fuel. In fact, the near elimination of overlapped areas allows us to apply inputs such as fertilizer with less than 1% of waste.

MANAGING RESOURCES AND ENVIRONMENTAL IMPACT

Our commitment to responsible agriculture does not end in the field. Once crops are harvested they are transported with aerodynamic Kenworth T680 trucks either to their final destination or to our grain system which is capable of storing over a million bushels of grain. Our grain system is powered almost entirely powered by our 360kWh solar array. To store grain long term we must ensure that the grain is dried to the proper moisture content using one of our two grain driers. Typically these systems use a lot of nonrenewable energy, such as propane, to accomplish the drying process. Because of the Kathleen A.P. Mathias Agriculture Energy Efficiency Program , we were able to replace a 35 year old, propane fueled grain drier with an electric one in April 2013. The new grain dryer has annually saved 3,200 kWh of electricity and 32,000 gallons of propane. All of these are simply components of our total farm system in an effort to manage our resources and impact on the environment through the entire production cycle.